This is how structural parts are produced

The tightening of global environmental protection regulations and the breakthrough of eMobility are forcing the development of new vehicle architectures. Aluminum lightweight structural components are designed to drive vehicle weight down further without sacrificing value or quality.

The complexity and, above all, the size of structural components in modern vehicle construction are constantly increasing. Complete vehicle floors and body parts, which in the past were welded together from individual parts, are produced from a single casting using the Gigacast process. The main advantage of this process is a significant reduction in the number of individual parts, but also improved crash properties of the entire body.

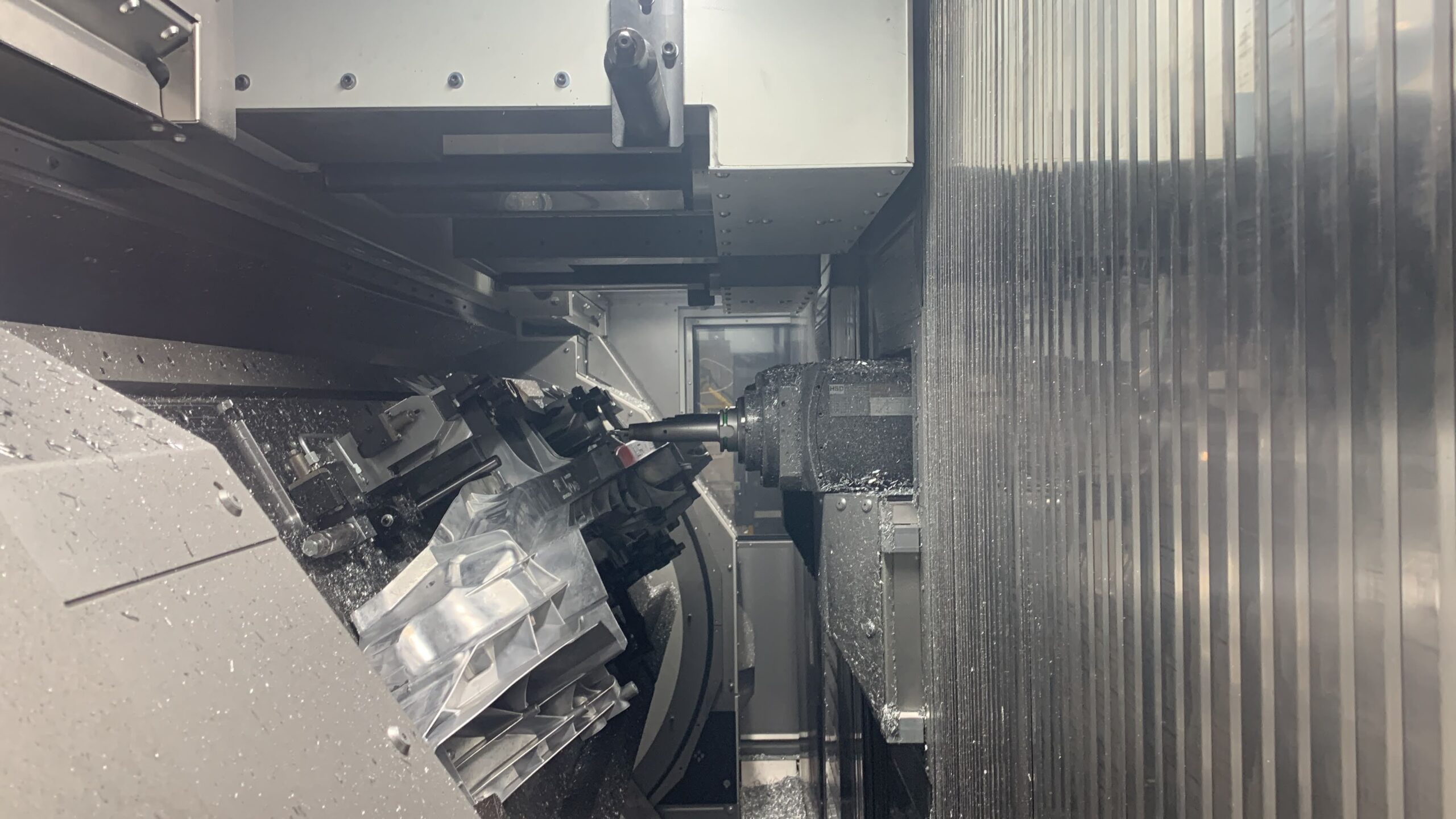

Machining of these Gigacast structural components requires equally large CNC machining centers. ANGER Machining has the right solution for parts up to 3.5 x 1.2 meters with the SP2-D and SP2-P, and with the Meteor 3000 there is even the possibility of clamping and double-spindle machining parts as large as 3.2 x 1.8 meters.

Manufacturing solutions in the production of structural components

ANGER MACHINING takes on the topic of structural components and in 2016 expanded its product portfolio with newly developed machining solutions specially adapted to the requirements. In doing so, ANGER MACHINING not only focuses on the processing machine itself, but also considers the entire manufacturing process, including the material flow between the individual process steps. Experience shows that there is great potential for savings in space requirements and in component logistics. Solutions for large components (up to 3,000 mm in length) are possible. Planning system control, fixtures, loading, the process and automation are all in our own hands. As a process architect, ANGER can thus ensure that the customer receives a fully process-capable production line that is perfectly tailored to the customer's needs.

MACHINING SOLUTIONS FOR STRUCTURAL AND E-COMPONENTS

The ANGER SP is a machining center for 5-axis machining of large-volume structural components such as side members, cross members, profile parts, battery trays, subframes, or others. It is the optimal solution when economical, precise and universal 5-axis machining of structural components is required. Due to the two independent machining units, 2 different components can be manufactured simultaneously.Suitable machines to produce Structural components

SP2-A

The ANGER SP2-A machine is the most efficient solution for processing extruded aluminum profiles. While both processing spindles are working on one processing bridge, loading and unloading takes place in parallel on the second bridge. The second clamping bridge swivels into the machining area in less than 2 seconds. Each tool is then machined alternately ... Read more

Learn more

SP2-D

The ANGER SP2-D machine is a flexible machining center for 4- or 5-axis double machining of large-volume components. The two processing units can process one component or different parts independently of each other. The large working area allows you maximum flexibility in process design and machining. With a clamping bridge of approx. 3,600mm length and ... Read more

Learn more

SP2-P

The ANGER SP2-P machine is a flexible machining center for 4- or 5-axis double machining of large-volume components. Two independent spindles process either 2 components synchronously or simultaneously a large component with a maximum length of 3,600 mm and a disturbance circle of 1,200 mm. The pallet changer enables loading and unloading to be carried ... Read more

Learn moreCustomer support