This is how transfer solutions work

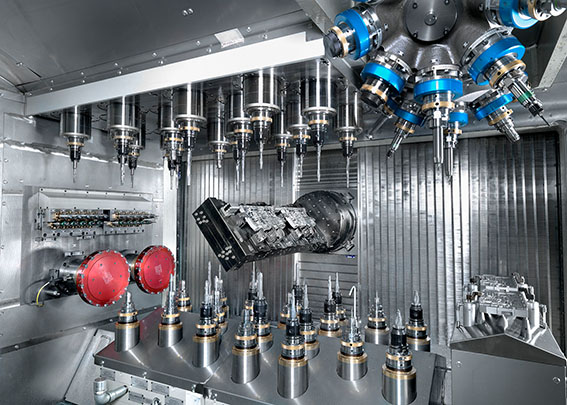

In a transfer center, components can be completely machined (milling, drilling, threading, etc.) in just one setup. The workpiece is machined in reverse compared to a conventional machining center. Workpieces are automatically clamped in a fixture and moved to the tools under CNC control. In most cases, several workpieces are machined at the same time.

It thus reduces space, energy, service and personnel requirements. Total cost of ownership (TCO) can be significantly reduced with this technology. Due to fixed spindles and the use of special tools, the highest accuracy requirements can be met.

Flexible low-volume production with optimized changeover time

ANGER MACHINING has developed a solution which opens up new possibilities for different workpieces with batch sizes from 10,000 pieces. With the 2PLUS, a new plant concept has been launched on the market that allows significantly greater variability. It enables flexible production of small batches with significantly reduced changeover time thanks to the innovative "SmartFix" zero point clamping system

SHORTER TIMES THROUGH INTELLIGENT TECHNOLOGY

In a machining center, the machining time is predominantly influenced by the tool change time. Depending on the quality and price of the tool changer, this takes between 2 and 6 seconds per change process (chip-to-chip time). 60-70% of the total machining time is thus accounted for by the tool change operations. In addition, there are several reclamping operations, since a workpiece usually has to be machined in several clamping positions in BAZ concepts due to the machining volumes.

REDUCTION OF MAIN TIME THANKS TO FLEXIBLE TOOLING

The ANGER multi-spindle heads enable the simultaneous use of several tools for productive multiple machining. HF spindles specifically designed for the task at hand also enable very high machining speeds. The mold design is not limited by the machine concept. This means that not only the auxiliary time but also the main time is decisively reduced.Suitable machines to produce Transfer solutions

HCX

The ANGER HCX Turn Key systems are specifically designed to meet the needs of the customers. The plant is designed, constructed and automated according to the specific parts. As a result, the highly productive HCX systems achieve the shortest cycle times with the highest accuracy. These are highly productive plants with maximum output rates. Depending ... Read more

Learn more

SP2-P

The ANGER SP2-P machine is a flexible machining center for 4- or 5-axis double machining of large-volume components. Two independent spindles process either 2 components synchronously or simultaneously a large component with a maximum length of 3,600 mm and a disturbance circle of 1,200 mm. The pallet changer enables loading and unloading to be carried ... Read more

Learn more

SP2-D

The ANGER SP2-D machine is a flexible machining center for 4- or 5-axis double machining of large-volume components. The two processing units can process one component or different parts independently of each other. The large working area allows you maximum flexibility in process design and machining. With a clamping bridge of approx. 3,600mm length and ... Read more

Learn moreCustomer support