This is how battery trays are made

The battery tray of an electric vehicle plays a central role, as it contains the battery, the heart of a purely electric or hybrid vehicle. In addition to the obvious task of enclosing and supporting the battery cells, safety-related requirements combined with weight and cost optimization pose the greatest challenge. Welded or die-cast aluminum trays are the method of choice because they can be mass-produced cost-effectively with low weight and high strength. Aluminum is also nearly 100% recyclable, underscoring the sustainable solution of e-mobility.

Battery trays for purely electrically powered vehicles (BEV = battery electric vehicles) are assembled and welded from individual extruded profiles, with these trays usually already constituting the complete vehicle floor.

Manufacturing battery trays for hybrid vehicles

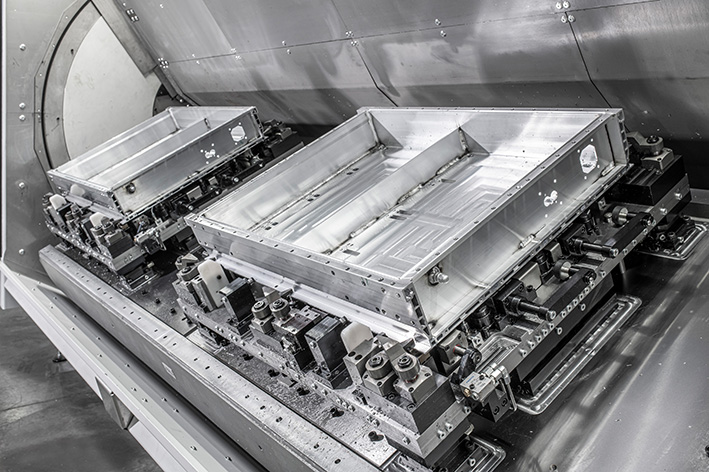

- Due to the more complex shapes, more complex tolerances and thin wall thicknesses, the clamping system of cast trays is of particular importance. Here, it is necessary to find the optimum of clamping forces, vibration damping and deformation with simultaneous flexibility (e.g. OP10 and OP20 in one clamping device).

- Depending on the required tolerances on the finished part, the blank must also be measured here by means of a probe or laser.

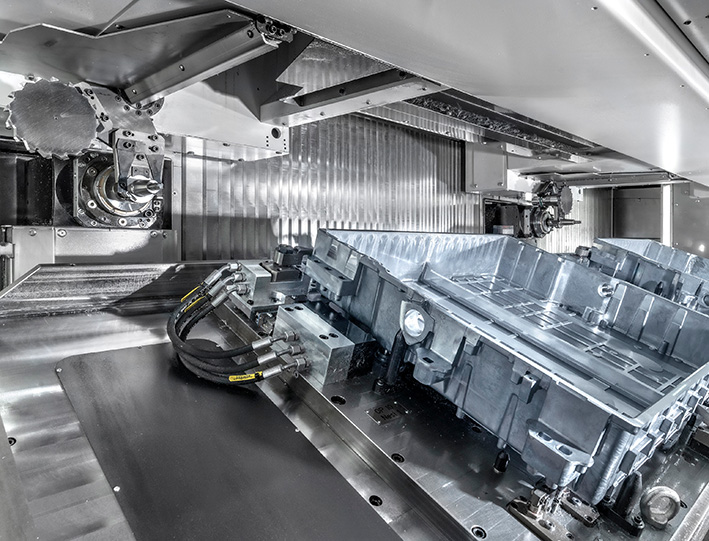

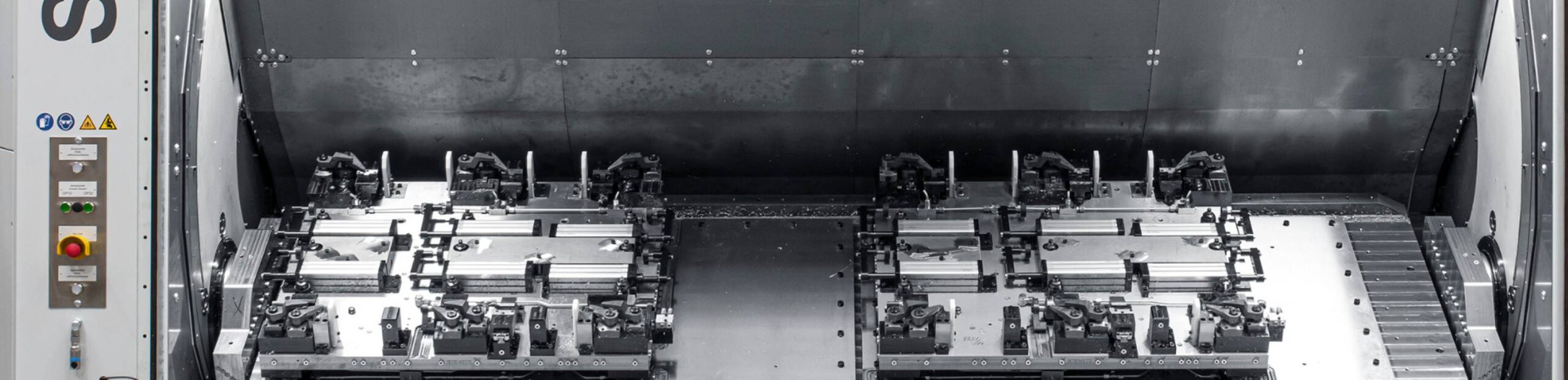

- The machining is done on the ANGER SP2-P or SP2-D. Both machines allow the synchronous double machining of two components or the machining of a very large component with two independent machining spindles.

Suitable machines to produce Battery trays

SP2-D

The ANGER SP2-D machine is a flexible machining center for 4- or 5-axis double machining of large-volume components. The two processing units can process one component or different parts independently of each other. The large working area allows you maximum flexibility in process design and machining. With a clamping bridge of approx. 3,600mm length and ... Read more

Learn more

SP2-A

The ANGER SP2-A machine is the most efficient solution for processing extruded aluminum profiles. While both processing spindles are working on one processing bridge, loading and unloading takes place in parallel on the second bridge. The second clamping bridge swivels into the machining area in less than 2 seconds. Each tool is then machined alternately ... Read more

Learn more

SP2-P

The ANGER SP2-P machine is a flexible machining center for 4- or 5-axis double machining of large-volume components. Two independent spindles process either 2 components synchronously or simultaneously a large component with a maximum length of 3,600 mm and a disturbance circle of 1,200 mm. The pallet changer enables loading and unloading to be carried ... Read more

Learn moreCustomer support